Integration between SAP PP and SAP EWM: Optimizing Production and Inventory Management Processes

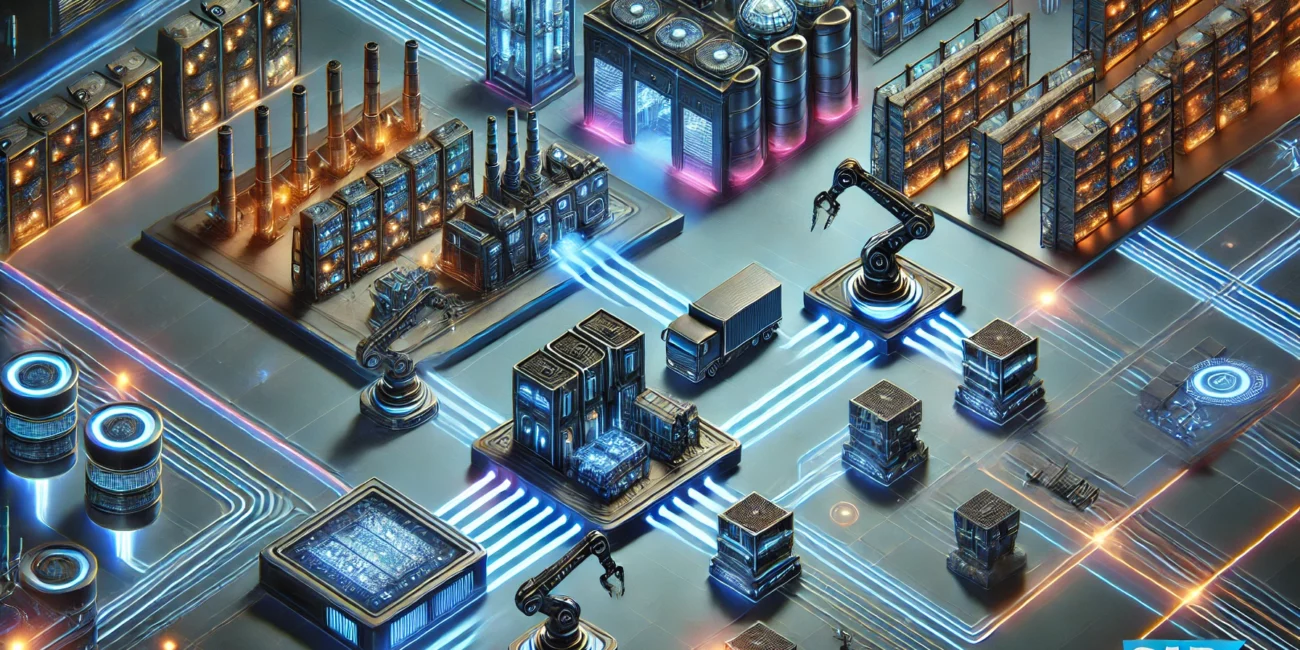

The integration between SAP PP (Production Planning) and SAP EWM (Extended Warehouse Management) is essential for companies aiming to optimize their production and inventory management processes. If you work in a production environment, you’ve likely encountered challenges related to material management, production planning, and logistics. This integration streamlines these processes and ensures that the right quantities of raw materials are available at the right time for production.

Introduction to SAP PP and SAP EWM Modules

SAP PP is the module responsible for production planning. It manages production orders, material requirements planning (MRP), and resource optimization.

SAP EWM, on the other hand, specializes in advanced warehouse management. It manages internal logistics flows, such as material storage, physical movements, and order preparation.

The integration of these two modules ensures seamless synchronization between production and logistics operations, which is critical in modern production environments.

1. Production Planning and Order Management in SAP PP

The process begins with planning in SAP PP, which relies on the BOM (Bill of Materials) and routing. The BOM (CS01 for creation) specifies the components required to produce a finished product, while routing (CA01 for creation) defines the production steps.

Here’s an overview of key objects used in SAP PP:

- BOM (Bill of Materials, CS01): The BOM lists the components and subcomponents needed for product manufacturing. For example, to manufacture a car, the BOM includes parts such as tires, engines, etc.

- Routing (CA01): It details the sequence of operations.

- Production Order (CO01): Created either automatically by MRP or manually, it uses the BOM and routing to determine the required components and production steps.

Once the production order is generated, the SAP system creates component requirements that need to be transferred from the warehouse, managed by SAP EWM, to the production floor.

2. Integration with SAP EWM: Inventory and Transfer Management

In SAP EWM, the transfer request for components is triggered by the production order in SAP PP. This request is converted into a warehouse task, which is then executed to move components from the warehouse to the production area.

Packaging and Handling Units (HU)

To optimize component transfers, SAP EWM uses Handling Units (HU; T-code: HU02), which group materials into physical containers (pallets, boxes, etc.). These units make it easier to track goods throughout their logistical journey, from the warehouse to the production floor.

Packaging Specifications

Packaging specifications play a crucial role in logistics optimization. They determine how materials should be packed into HUs to maximize storage efficiency and minimize unnecessary movement.

The steps for creating packaging specifications in SAP EWM are as follows:

- Defining packaging levels: For example, a box as the base unit and a pallet as the higher-level unit.

- Assigning materials to packaging: Each BOM component is associated with a packaging specification that defines how it will be grouped into an HU.

- Optimizing HUs: By applying packaging rules based on criteria such as volume, weight, and container type, transfers are optimized to reduce costs.

3. Work Stations: Manual and Automatic Workstations in SAP EWM

In SAP EWM, work stations are critical points where packaging instructions are executed as per the packaging specifications. These stations organize the preparation of materials destined for production. From my professional experience, I have had the opportunity to work with hybrid work stations (manual and automatic), where both systems coexist. This approach offers various advantages and disadvantages depending on production needs and the type of materials being handled.

Manual Work Stations

Operators manually prepare components using Handling Units to group materials needed for production. This method is flexible but may be slower.

Automatic Work Stations

In contrast, automated systems or robots can be used to manage HUs and execute packaging specifications with high precision and speed.

4. Execution of Production and Return of Finished Products

Once the components are transferred to the workshop, production can begin. The HUs are scanned upon entering the production area, and the information is updated in real-time in both SAP PP and EWM, confirming the availability of materials.

After production, the finished products are also packed into HUs and transferred to the warehouse for storage or shipment, ensuring complete traceability through the integrated systems.

No Comment! Be the first one.